Hotel Astoria Bad Hofgastein

A healthy new start in wood

For several years, the venerable Hotel Astoria in Bad Hofgestein's prime location lay deserted. The former glory will now be resurrected under new ownership. The new owner, a Belgian tourism group specialising in health holidays in the mountains, is not only reviving the existing building through a partial general renovation, but is even implementing an extensive expansion.

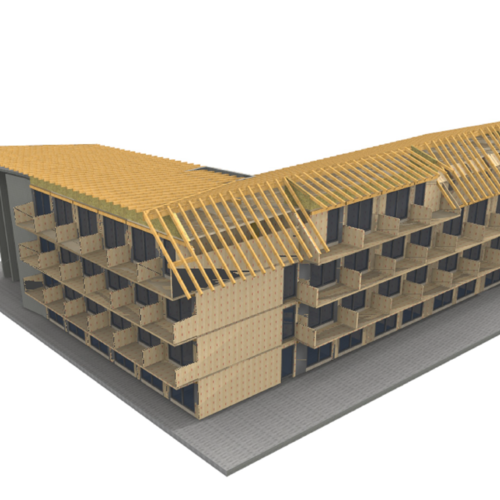

Expansion in CLTPLUS

The angular existing building with a long transom oriented towards the street is extended by an underground car park behind the building. On top of this underground car park, a new four-storey room wing is being built, also in an angular design. This arrangement will create a contained inner courtyard. A new media wing for events complements the hotel's future facilities. Apart from the underground car park and the staircase, the entire expansion is being built in solid wood. The timber construction companies Holzbau Egger and Holzbau Burgschwaiger worked together with TEAMTHEURL on all details, such as beam constructions, window details or door and window cut-outs in the CLT elements. 70 m3 of glued laminated timber were used, e.g. for the beams, as well as 650 m3 of high-quality CLTPLUS, from which the walls and ceilings are made. The outer walls are 10 cm thick and the interior has exposed wood quality and thus remains untreated. Different panel thicknesses (10 cm, 12 cm and 14 cm) were used for the ceilings. They are also partly finished in visual quality. The partition walls (10 cm and 12 cm thick) will be partially visible without encapsulation. The roof construction with a volume of around 900 m3 required an additional 50 m3 of construction and glulam timber. An interesting detail is the arcade near the staff rooms: Here, the storey ceiling is cantilevered.

During planning and execution, the fire protection as well as the sound and thermal requirements for the project must be taken into account at all times. To be able to guarantee this, these requirements and designs must be coordinated and agreed with all companies on site. The assembly and joinery plans were drawn up using the SEMA timber construction programme. This guarantees the seamless exchange of data between Theurl and the customer and at the same time enables correct data preparation for the production of the partly complex timber components.

Smooth logistics

It was possible to transport all the building material to the Gastein Valley with a total of 14 truckloads. The good cooperation with reliable logistics partners also made deliveries possible at short notice. Since Theurl was able to provide empty trailers in Steinfeld, the haulier did not have to put up with any waiting times.

Timber master-builder Martin Egger

"The challenges in this project were the details and implementations for fire protection and sound insulation. When optimising the walls and ceilings, care was taken to use resources sparingly. The assembly sequence of the 4 floors was included in the factory planning. The new building was thus divided into 2 assembly sections and one level with the ceiling above was assembled in each assembly sequence. The exchange of data and the transfer of the Sema file among each other is indispensable for the factory planning stage. Comprehensive detail and execution planning before the start of construction is standard nowadays and saves additional costs and valuable time afterwards."