Glued laminated timber

The challenging living conditions in the mountains strengthen the resilience of the spruces. Spruce wood is therefore the perfect material for our glued laminated timber production. Easy workability and high strength are the key characteristics and qualities of glued laminated timber.

More than standard, clever solutions

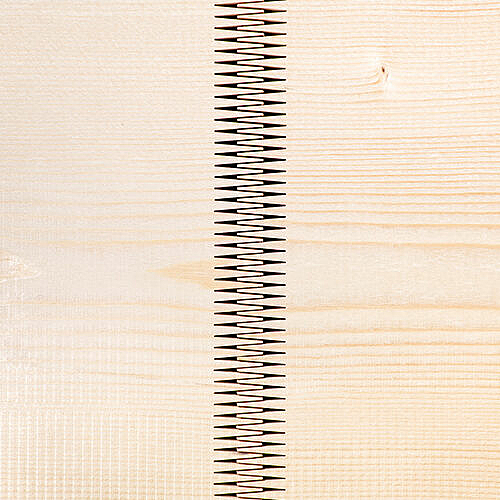

THEURL glued laminated timber is made of at least two lamellas. The load capacity is much greater than that of conventional timber, due to the layered structure. Another quality characteristic is the selected knotless wood, which is glued parallel to the fibre and planed on four sides, resulting in aesthetically pleasing functional components. The automatic testing of each individual lamella is standard. The exact strength class is determined by the Microtec GOLDENEYE, pursuant to Önorm EN 14081-1.

Anything is possible

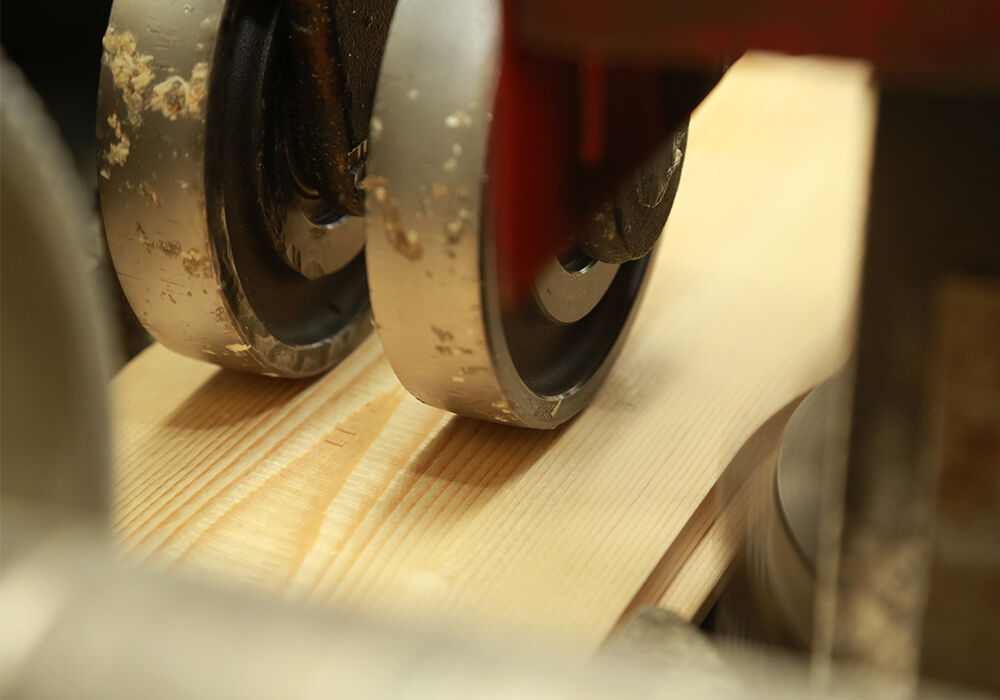

There is a solution for everything – even the most complex wooden structure. We convert your project into impressive, high-quality CNC components. State-of-the-art processing machines cut wood into any

shape quickly and precisely. Together with our customers, we are aiming to take timber construction into a new dimension.

Everthing under one roof

With computer-assisted manufacturing, THEURL meets the highest precision and quality requirements of modern timber construction. In our assembly facilities, we carefully and expertly produce individual wooden structures measuring up to 18 m in length and 1.25 m in height. The years of experience of our employees and the high precision of the three joinery machines play an important role in this. They guarantee sustainable customer service. Specifically, everything from the realisation of the design as ready-to-install and millimetreaccurate components, to the quality control at the end of processing, is covered.

The joinery service - a quantum leap

Our joinery service centre combines traditional manual work with modern technology. It serves as an interface through which we can fully meet the needs and requirements of our customers. Initial consultation: Your project is accepted, a plan is drafted, and the costs are calculated. The wooden components then take shape in the joinery station. The state-of-the-art joinery station allows millimetre-precise production in no time. This enables a high degree of fl exibility thanks to fast and optimal construction while keeping to the deadlines, as well as through calculable cost savings and top-quality construction elements.