The future beginns with CLTPLUS

Energy-efficient, durable, recyclable, extremely resistant and CO2 neutral: Could a construction material be any more versatile? At least three layers of cross-laminated board make CLTPLUS an almost universally applicable, particularly stable product: the large-format solid wood CLTPLUS boards are used to form wall, ceiling or roof elements. The high level of pre-fabrication permits short construction times without drying phases. CLTPLUS in a quality that does not require masking also creates a comfortable atmosphere and high room quality.

Wall applications

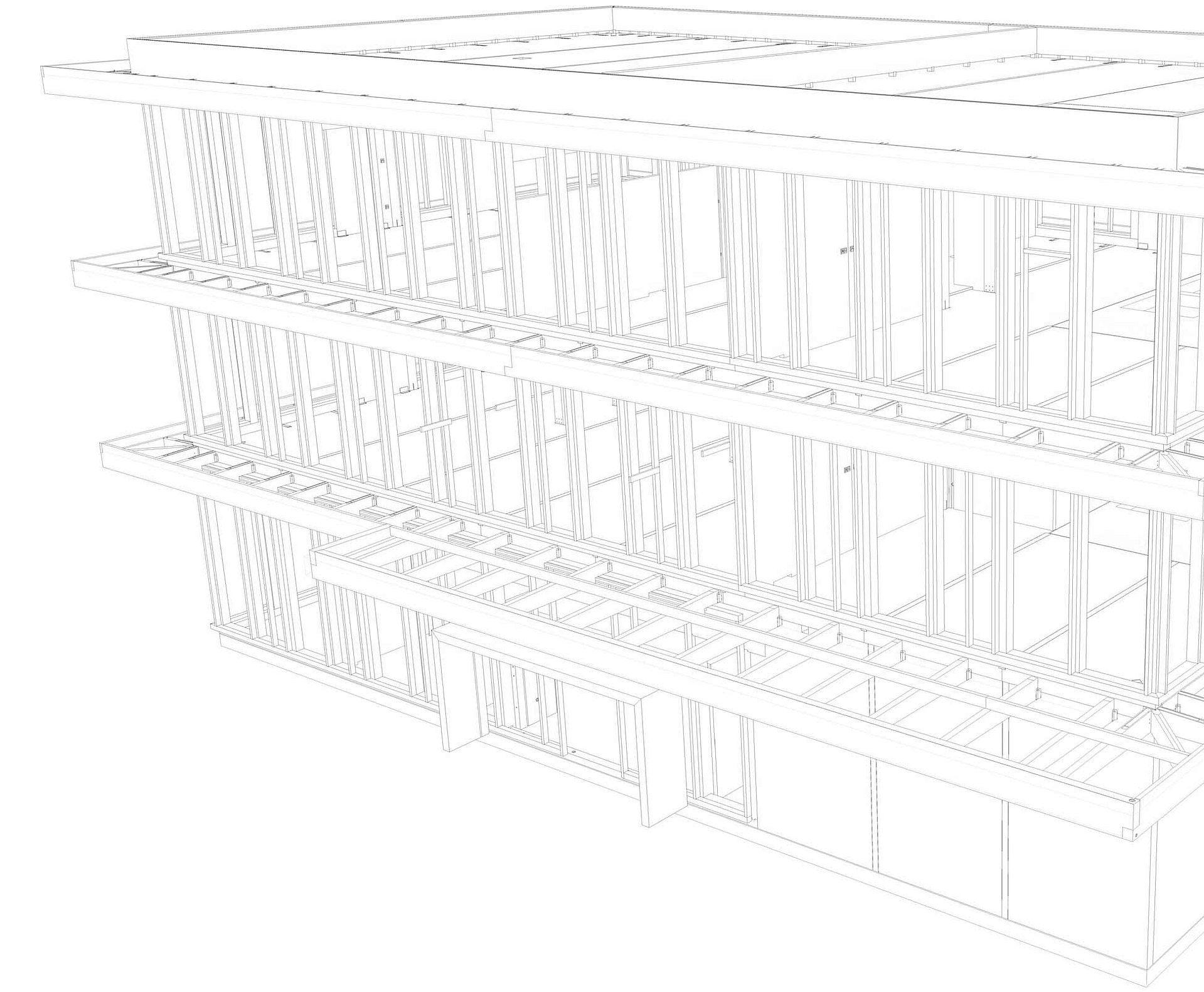

One building product, unlimited uses. The structural and static benefits of CLTPLUS make it a real all-rounder in component planning. As an element with high static and stiffening properties, it can absorb and safely dissipate excessive vertical forces. Its excellent, characteristic insulating properties make it particularly interesting for the low-energy and passive house standard. Wall elements made of CLTPLUS also ensure a balanced room climate.

Roof and ceilings applications

The requirements of large spans with low component heights make CLTPLUS a good choice for ceilings and roof construction. Rigid and dimensionally stable, the components are able to dissipate horizontal loads in the corresponding static system. The high degree of prefabrication of the components guarantees that the next floor can be installed quickly.

| Element type | Thickness (mm) | Element structure / lamella thickness (mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| L | C | L | C | L | C | L | ||

| L3 | 60 | 20 | 20 | 20 | ||||

| 80 | 30 | 20 | 30 | |||||

| 90 | 30 | 30 | 30 | |||||

| 100 | 30 | 40 | 30 | |||||

| 120 | 40 | 40 | 40 | |||||

| L5 | 100 | 20 | 20 | 20 | 20 | 20 | ||

| 120 | 30 | 20 | 20 | 20 | 30 | |||

| 140 | 40 | 20 | 20 | 20 | 40 | |||

| 160 | 40 | 20 | 40 | 20 | 40 | |||

| 180 | 40 | 30 | 40 | 30 | 40 | |||

| 200 | 40 | 40 | 40 | 40 | 40 | |||

| L5 ⸱ 2 | 160 | 30 ⸱ 2 | 40 | 30 ⸱ 2 | ||||

| L7 | 180 | 30 | 20 | 30 | 20 | 30 | 20 | 30 |

| 200 | 20 | 40 | 20 | 40 | 20 | 40 | 20 | |

| 220 | 40 | 20 | 40 | 20 | 40 | 20 | 40 | |

| 240 | 30 | 40 | 30 | 40 | 30 | 40 | 30 | |

| L7 ⸱ 2 | 180 | 30 ⸱ 2 | 20 | 20 | 20 | 30 ⸱ 2 | ||

| 200 | 30 ⸱ 2 | 30 | 20 | 30 | 30 ⸱ 2 | |||

| 220 | 40 ⸱ 2 | 20 | 20 | 20 | 40 ⸱ 2 | |||

| 240 | 40 ⸱ 2 | 20 | 40 | 20 | 40 ⸱ 2 | |||

| 260 | 40 ⸱ 2 | 30 | 40 | 30 | 40 ⸱ 2 | |||

| 280 | 40 ⸱ 2 | 40 | 40 | 40 | 40 ⸱ 2 | |||

| L8 ⸱ 2 | 300 | 40 ⸱ 2 | 30 | 40 ⸱ 2 | 30 | 40 ⸱ 2 | ||

| 320 | 40 ⸱ 2 | 40 | 40 ⸱ 2 | 40 | 40 ⸱ 2 | |||

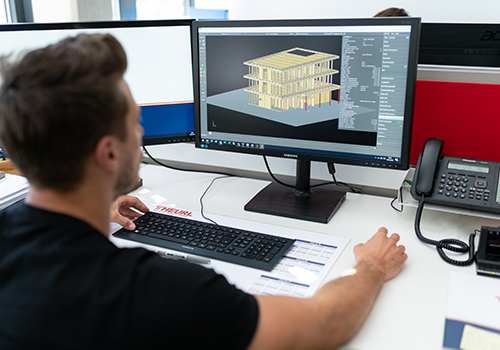

CAD joinery: a virtual data framework

Our internal, technical timber construction team works closely with our customers to ensure that your components are manufactured exactly according to plan. Our systems support all common CAD programs such as SEMA, Dietrich’s, CADWork and HSB CAD. This enables us to communicate in the “native design language” of our customers.

Our service

The success of your project lies close to our hearts. With our one-stop shop philosophy, we support our customers throughout project development as closely as possible. There’s no confusion about our responsibilities, with us you will always have the right partner at your side – for everything from receiving your initial enquiries, through consultation, to technical project management.

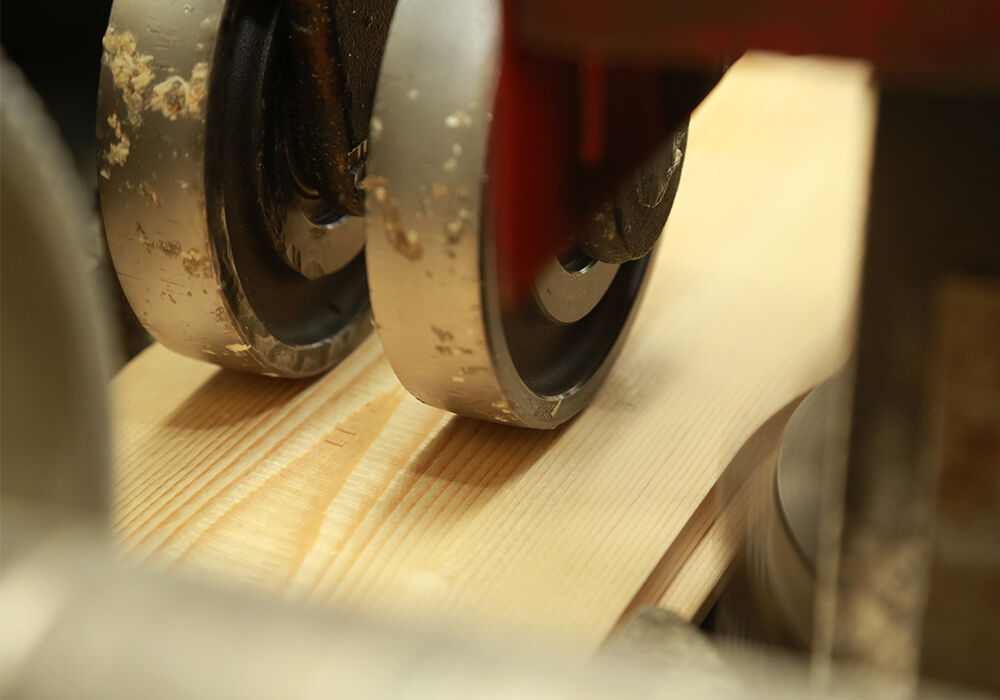

Joinery service centre

The components are joined, fully automatically, in our joinery centre on the basis of the approved production and cutting plans. Our joinery systems can manufacture complete components for wall or floor elements from the master panels. Automated laser measurement of components determines the position of the elements on the production line with millimetre accuracy and thus guarantees the highest level of manufacturing precision. To ensure that the elements reach the construction site safely after they have been cut, they are packed and loaded together onto trucks according to design layout.

Joinery services

+ Formatting at right angles to the panel surface

+ Ceiling and wall timber framing – cut at right angles for the

panel surface

+ Machined on both sides

+ Outlets and openings for beams, purlins and rafters

+ Deep-hole drilling electrical installation

+ Post-machining of corner curves