We drive cars whose rear and front windows are glued. The reinforcing effect of the glazing is factored into all tests and crash tests. Almost every subway, almost every bus has a static load-bearing bond – and is approved for transport. Only in the construction sector does glass-wood bonding prove to be a little more difficult.

More than 10 years ago we took part in a project of Holzforschung Austria (Austrian Forest Products Research Society), which posed the question: How can glass be structurally reinforced with wood? The motivation behind this was the plastic window industry. They began gluing glass into the frame, and leaving out the steel inserts. This was mainly due to the weight and price savings, as well as for thermal engineering and structural reasons. Today, static insulating glass is glued into 90% of all plastic windows. So, inspired by the plastic window industry, Austria's wooden window manufacturers asked themselves: Why can't we glue glass into our wooden windows? That was where we came in. We took part in the research project, made our products available and carried out countless bonding trials with all manner of adhesive materials.

Bonding trials

We tried epoxy resins, polyurethanes or polysulphides and none of it worked. It wasn’t until we realised that the clue was to protect the wood. When we glue glass onto wood, the glue forms a protective layer on the wood surface. That was the trick. It was now possible to omit surface treatment of the wood and glue our glass directly onto the wood. The adhesive also offered protection and acted as a preservative for the product. This works wonderfully with silicone. In other words, when we glue glass to a birch veneer plywood strip, we're bonding onto the raw, untreated surface.

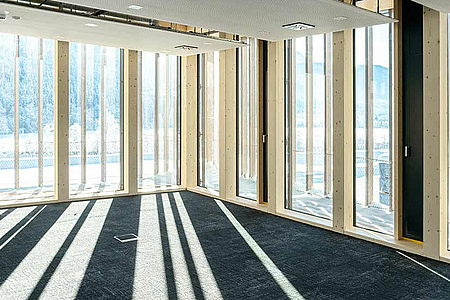

We combine a glued laminated timber design with an insulating glass element, which is bonded at the factory with a birch veneer plywood strip, so that trial bonds are screwed directly into the wooden construction. The glass then has a stiffening effect. The essential element, the insulating glass, is manufactured by us and bonded in the workshop to a plywood strip which is then screwed into the design on the construction site. Of course, the facade composite must meet some structural requirements.

Hanspeter Petschenig, Uniglas Facade

Hanspeter Petschenig is a graduate of the Glasfachschule (School of Glass) in Kramsach. He then followed this by training to become a glazier, glass cutter and mirror fitter with a master's degree. While still studying, Petschenig performed prominent roles in several international projects. Today the CEO of Petschenig glastec GMBH puts his extensive knowledge at the service of the public - as a contributor to ÖNORM committees and as a lecturer in Facade Technology at DHBW Baden-Württemberg Cooperative State University.